Discover Undercarriage Parts for Heavy Equipment

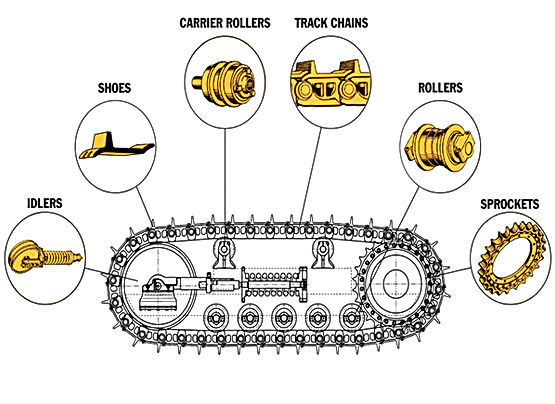

Understanding the intricacies of undercarriage components is crucial for the ideal performance and durability of hefty machinery. From track footwear to gears, rollers, and idlers, each part plays an essential role in the functionality of the equipment.

Significance of Undercarriage Components

The undercarriage parts of heavy equipment play a crucial function in guaranteeing the total performance and durability of the devices. These parts, including tracks, rollers, sprockets, idlers, and chains, form the structure whereupon the maker runs. A properly maintained undercarriage not only gives security and support to the hefty equipment yet additionally adds considerably to its functional effectiveness and performance.

Among the vital benefits of buying top notch undercarriage components is the reduction of downtime and maintenance costs. By utilizing long lasting parts that can stand up to the rigors of sturdy applications, operators can minimize the requirement for constant fixings and replacements, thus taking full advantage of the equipment's uptime and overall lifespan.

In addition, appropriately operating undercarriage parts ensure optimum weight maneuverability, circulation, and grip, permitting the hefty equipment to operate smoothly also in challenging surfaces. This reliability is important for industries such as building and construction, mining, and agriculture, where devices efficiency straight affects job timelines and earnings. In final thought, the importance of undercarriage components can not be overstated in preserving the efficiency and durability of hefty machinery.

Sorts Of Track Shoes

When considering the numerous kinds of track shoes for heavy machinery, it is important to examine their design and performance in regard to details functional requirements. Track footwear are important parts of the undercarriage system, supplying weight, grip, and stability distribution for heavy machinery such as excavators, excavators, and crawler cranes.

One of the most usual types of track footwear include:

** Grouser Shoes **: Including elevated metal bars (grousers) along the shoe's surface area, these track footwear give boosted traction in tough surfaces like mud, snow, and loosened gravel. undercarriage parts.

** Double Grouser Shoes **: Similar to grouser shoes but with an additional set of grousers, these track shoes supply also higher traction and stability, making them perfect for very rough terrains.

** Three-way Grouser Shoes **: With three sets of grousers, these track footwear offer maximum grip and security, making them appropriate for the most requiring conditions.

Picking the ideal sort of track footwear is important for maximizing the performance and durability of heavy equipment while making sure safety and effectiveness during operations.

Feature of Rollers and Idlers

Rollers and idlers play indispensable roles in sustaining and directing the track shoes of hefty equipment throughout operation. By stopping extreme slack or rigidity in the tracks, idlers add to the total security and efficiency of the machinery.

Furthermore, rollers and idlers collaborate to maintain the track footwear abreast, preventing them from slipping or hindering off during procedure. Appropriately functioning idlers and rollers are critical for ensuring the long life of the undercarriage system and making best use of the equipment's efficiency. Regular maintenance and evaluation of these components are vital to identify any type of indicators of wear or damages at an early stage, protecting against pricey repair work and downtime in the future.

Duty of Sprockets in Equipment

Upkeep Tips for Undercarriage Components

Efficient upkeep of undercarriage parts is important for making certain the durability and ideal efficiency of hefty equipment. Normal examination of undercarriage parts such as track chains, rollers, idlers, sprockets, and track footwear is essential to stop unforeseen malfunctions and pricey fixings. One essential upkeep pointer is to maintain the undercarriage tidy from debris, mud, and other contaminants that can speed up wear and rust. It is likewise crucial to make sure correct track tension to stop premature wear on elements. Greasing the undercarriage parts at suggested periods aids to minimize rubbing and prolong the life expectancy of the elements. Checking for any type of unusual sounds, vibrations, or changes in machine performance can indicate possible concerns with the undercarriage that call for instant attention. By following these upkeep ideas faithfully, heavy equipment drivers can lessen downtime, decrease operating costs, and maximize the performance of their devices.

Conclusion

Finally, the undercarriage parts of heavy machinery play a crucial function in ensuring the smooth performance and longevity of the equipment. YOURURL.com Comprehending the relevance of track shoes, gears, rollers, and idlers, along with implementing appropriate upkeep practices, can significantly influence the total performance and effectiveness of the equipment (undercarriage parts). Routine examination and timely replacement of damaged components are vital in making the most of the life-span and performance of hefty machinery

Rollers and idlers play essential functions in sustaining and assisting the track footwear of hefty machinery during operation.In heavy machinery, sprockets serve a critical feature in moving power from the engine to the tracks, enabling the equipment to move efficiently and efficiently. These elements are linked to the axles or last drives of the machinery and work in conjunction with the tracks to push the devices ahead or backwards. Routine assessment of undercarriage components such as track chains, rollers, idlers, gears, and track shoes is important to stop expensive repair services and unforeseen malfunctions. Comprehending the significance of track shoes, idlers, gears, and rollers, as well as implementing correct upkeep methods, can significantly impact the total efficiency and effectiveness of article the machinery.